Ten years ago this week I was sitting in the shared conference room of a San Diego apartment building drawing out ideas with the founding members of Fuse as we asked the question “what could Fuse be?” We talked about grand theories of Navy networking, and software, and how to push forward the defense technology enterprise into more innovative and user-focused realms. Three creative minds, working out how to combine our experience and expertise to take on the world!

That is a pretty common beginning of the story for entrepreneurs… and one that more often than not ends in defeat. But ten years later, with a strong and growing company built on top of an exceptional team, the Fuse story is one of success! The vision of bringing the best practices of Design Thinking to defense technology is one that has set us apart. And the TEAM of people here under our roof is what has made all the difference. Our team is a beautiful mixture of operational experience, and engineering expertise. Our operator reps, and project managers have more experience in the field than I could ever imagine; and our engineering staff has more expertise than I could try to pack into my own lifetime of learning. The camaraderie, teamwork, and shared vision here at Fuse, with ten years of hard work under our belts, is what truly makes us great.

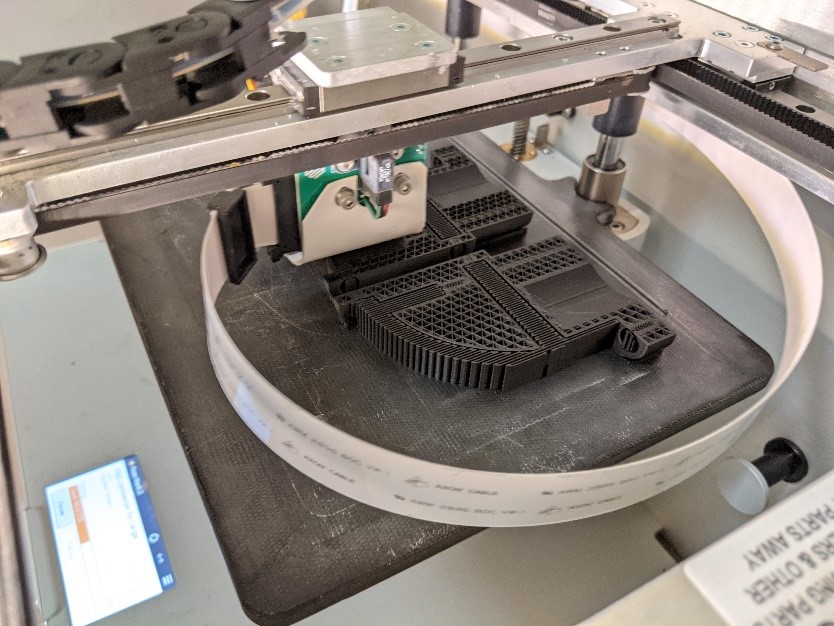

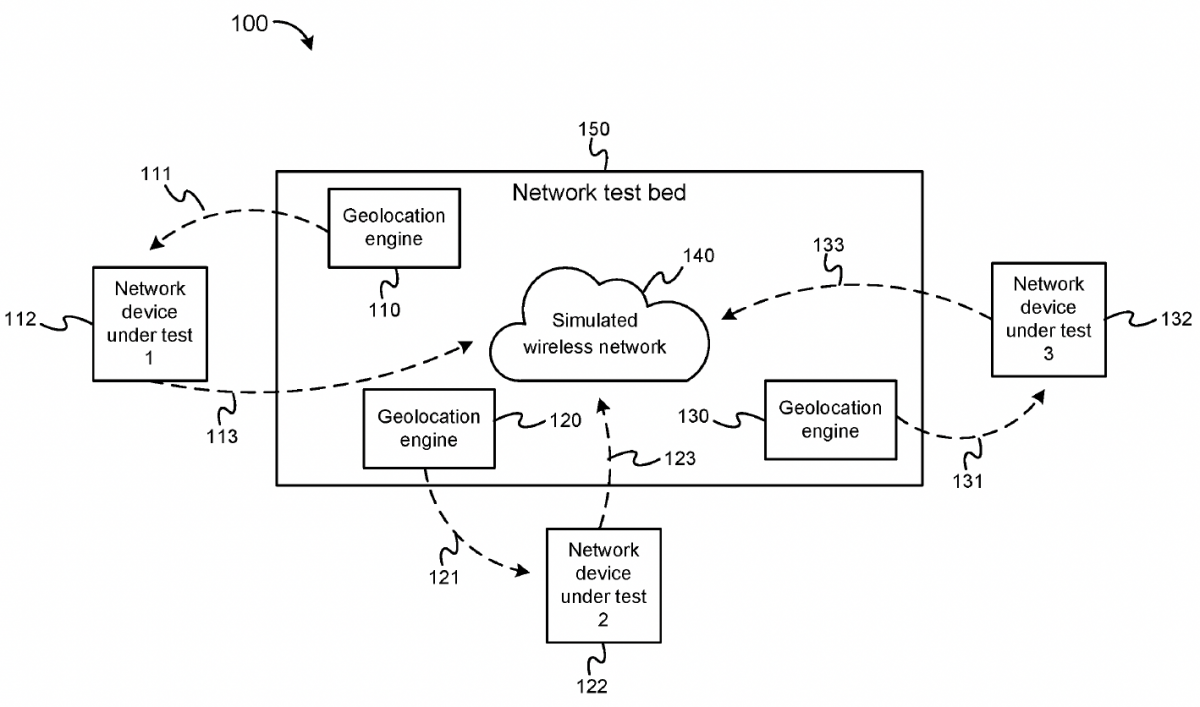

It is exciting to sit down and write about where we are, how we got here, and where we are going. It is awe-inspiring to consider the excellence of the TEAM that keeps us moving, and it makes me so proud as I stand in front of Admirals, Generals, and captains of industry telling the story of how our products and solutions make a significant difference to the warfighters who defend our nation. Fuse is building software defined networking systems that are changing the way operators communicate, along with rugged servers for aircraft and unmanned systems. We are building software that gives operators unprecedented vision into complex systems running on remote vehicles deployed around the world. We are building technical solutions for Fighters and Command and Control aircraft that make it easy and intuitive to stay connected, to communicate, and to accomplish the mission. We got here by being passionate about our work, believing there is always a solution within reach, and caring about each other as a team.

Since 2010 we have worked through ups and downs. Like any good startup we went through periods of trying to figure out what we would do ‘when we grew up’ and adjusted our approach, our process, and our products. While at the 10 year mark I feel like we have learned a lot, I don’t think we are anywhere near the end of our evolution and learning. Our products are more refined, or processes have become more detailed and consistent; and we still have so much more to do. There are and will be more challenges, upsets, and victories to come.

Fuse is transitioning from research and development to fieldling and supporting our products. We continue to innovate and grow with a rapid-prototyping approach that is tightly connected to the user. And in the next ten years I am confident we will see deployment of our systems on a wide variety of platforms and deep into multiple markets.

It is exciting to think about what the future holds for Fuse, and it is exciting to come to work every day with a team so passionate and capable. I am proud of the first 10 years of Fuse and the incredible team that has made it possible, and I look forward to what lies ahead.